Intelligent Grinder, Polisher, and Cleaner is a fully automated equipment that combines grinding, polishing, and ultrasonic cleaning functions into one machine, making the entire experiment process simpler and more efficient! With this machine, you can save up to 95% of operation time!

Equipped with four platens, the Intelligent Grinder, Polisher, and Cleaner eliminates the need for frequent changes of sandpaper or diamond disks. Its built-in ultrasonic cleaning function thoroughly removes residues from samples, preventing contamination and ensuring that every sample is clean and reliable for each experiment.

The intelligent grinder, polisher, and cleaner also has additional features to ensure that samples are processed with both flatness and consistency.

● Grinding head can move horizontally which enhances grinding efficiency.

● Individual force and central force

● Precise digital controls for grinding depth and pressure

For safety concerns, the machine is equipped with a grating safety protection system, providing comprehensive security during operation.

Whether for metallography, material research, or industrial testing, the Intelligent Grinder, Polisher, and Cleaner delivers an all-in-one, high-efficiency solution, making experiment work easier and more reliable.

※Mobiles and tablets can be slid left and right.

Adjustable head rotation speedThe rotation speed of the head covers a wide range, allowing flexible adjustments based on the material and characteristics of the sample to meet the requirements of various materials.

Micro-speed grinding and polishing function

It is ideal for long-duration precision grinding and polishing operations, especially for sample preparation requiring zero deformation.

Individual force: Digital control and stable air pressure supplyAllowing users to precisely set the appropriate pressure based on the characteristics of the sample and preparation requirements.

Precision micro-pressure adjustment (Option)An optional precision micro-pressure adjustment feature is available, specifically designed for sample preparation requiring delicate handling. This lightweight pressure application is ideal for fragile, sensitive, or low-pressure samples, ensuring no stress damage or deformation occurs during the preparation process.

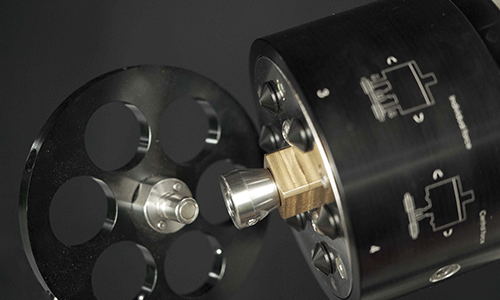

Central forceEnsuring uniform force is applied to the sample during grinding and polishing, further enhancing surface flatness and consistency. Featuring a quick-release design, the sample holder can be easily removed for convenient cleaning or leveling operations.

Versatile platen options for various consumables Available in two platen sizes, 8” and 10”, allowing users to select the appropriate size and type based on sample requirements and experimental conditions. Grinding platens are suitable for use with consumables like waterproof SiC papers, while polishing platens are compatible with polishing cloths. Additionally, magnetic platens are available for flexible applications, meeting diverse sample preparation needs.

Rinse and spin cleaning functionEquipped with a rinse and spin cleaning function, the machine can rapidly clean the surface of grinding and polishing consumables surface, ensuring immediate cleanliness after each sample preparation step. This design not only enhances operational convenience but also effectively reduces cleaning time, further accelerating the overall sample preparation process.

Overload protectionEquipped with an automatic overload protection function, it monitors pressure during operation to ensure it does not exceed the factory-preset safety value. If the pressure goes beyond the safe range, the machine will immediately stop operation to prevent potential mechanical damage or sample deterioration, providing an additional protection.

Linked dispenser systemThrough the human-machine interface, dosing parameters can be easily set to achieve precise and stable polishing liquid supply. Users can adjust the dosing rate and time according to the sample material and polishing requirements, ensuring controllability and high reproducibility of the polishing process.

Combine grinding, polishing, and sample cleaning functionsNot only equipped with grinding and polishing capabilities, but also provides a sample cleaning function, making it a multifunctional, all-in-one sample preparation machine. After grinding or polishing, operators can directly use the cleaning function to quickly remove residual dust and polishing liquids from the sample surface, significantly saving time and improving the efficiency of the sample preparation process.

Intelligence CleaningAfter the grinding/polishing process is completed, the grinding head automatically positions itself at the cleaning tank to initiate the cleaning procedure, eliminating the need for additional manual cleaning. This significantly saves manual labor resources.

Ultrasonic CleaningCombining automatic ultrasonic water cleaning and drying functions, the cleaning process can be performed without removing the sample platen or samples. This prevents cross-contamination during the preparation process and significantly improves work efficiency.

No need to replace consumables during grinding/polishingWith the innovative four-platens design, users can perform grinding and polishing operations without frequently replacing consumables, optimizing the workflow. This design not only significantly reduces operation time but also minimizes labor requirements, enhancing overall grinding and polishing efficiency.

Save nearly 95% of operator timeCompared to traditional cleaning methods, users can easily complete the sample cleaning process with the one-touch automatic cleaning function, significantly reducing the time spent on manual cleaning by nearly 60%.

Grinding depth can be set and auto adjustmentThe calibration function enables precise control of grinding depth, allowing users to set the desired grinding depth through the touch panel. During the grinding and polishing process, the machine automatically adjusts the grinding depth. The grinding depth range can reach up to 5mm, with a minimum adjustment increment of 0.01mm. This feature not only ensures high precision but also provides exceptional ease of operation.

Oscillating grinding head enhances grinding efficiencyThe left-right oscillation design of the grinding head effectively enhances efficiency and uniformity during the grinding process. This design enables the grinding head to cover a larger grinding/polishing area through oscillation, effectively preventing excessive wear of consumables in specific areas, extending their lifespan, and further reducing operating costs.

Environmentally friendlyUtilizes ultrasonic water cleaning to clean samples effectively without the need for chemical cleaning agents. By accelerating water molecules through ultrasonic vibrations, it penetrates the sample surface and tiny gaps, effectively removing contaminants, dust, and polishing residues. This ensures the cleanliness of the samples while reducing environmental pollution.

10 memory modules, each capable of storing 4 sets parametersEquipped with a high-resolution color touch panel and an intuitive human-machine interface design, the system includes 10 memory modules, each capable of storing 4 sets different parameters. This allows users to quickly switch between and save various grinding programs with ease.

LED lighting enhances observationThe high brightness and uniform illumination design of the LED lights provides users with an excellent observation environment after grinding and polishing operations. The high brightness improves visibility, helping users quickly identify the results of grinding and polishing.

Grating safety protection deviceUsing a high-precision optical sensing system, this device provides safety protection for operators and equipment. By utilizing the principle of beam interruption, it instantly triggers a shutdown mechanism upon detecting foreign objects or human presence near the work area, effectively preventing accidents.

Three-color light design simplifies machine status monitoringWith a simple and intuitive three-color light design, users can quickly understand the real-time status of the machine without detailed inspections, improving work efficiency and operational convenience.1.When the red light is on, it indicates that the machine is in an emergency stop state or has encountered an abnormal situation.2.When the yellow light is on, it indicates that the machine is performing a homing process.3.When the green light is on, it means the machine is in normal operation, with a stable workflow requiring no additional intervention.

Please visit our Contact Us for more information about the machines!