Metallographic pretreatment reveals the microstructure of materials through precision cutting, mounting, grinding and polishing, assists quality control, failure analysis and development of new materials, improves product performance and reliability, and promotes breakthroughs in advanced process technology.

Read More >

Metallographic preparation steps, including needs assessment, vise design, cutting, cold or hot mounting, planar grinding, rough polishing, final polishing, etching, microscopic analysis, reveal the material´s microstructure to assist in quality control and failure analysis, enhancing product reliability.

Read More >

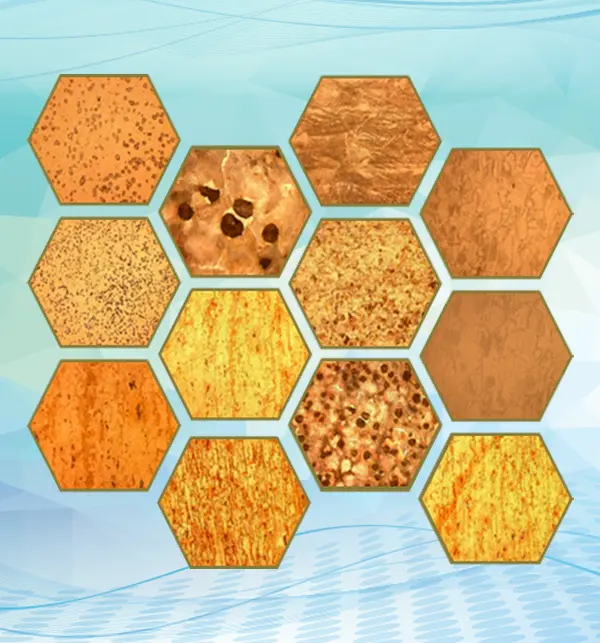

Metallographic analysis is carried out by performing cutting, mounting, grinding, and on the polished cross-section, selective etching of the grain boundaries is performed.The cross-sectional morphology, grain structure, and phase composition of the material are observed under a microscope, allowing the deduction of its three-dimensional compositional structure.

Read More >

Metallographic cutting machines can be divided into two main categories: precision cutting machines and precision diamond saw. Their primary purpose is to cut samples into sizes suitable for subsequent mounting and polishing. The goal is to preserve the integrity of the samples, avoiding thermal or physical damage during the cutting process, in order to ensure the accuracy of subsequent analyses.

Read More >

There are two metallographic mounting techniques: cold mounting and hot mounting. Mounting techniques are crucial for protecting the sample and improving grinding and polishing efficiency, and it is essential to select the appropriate mounting press and consumables to ensure the accuracy and consistency of metallographic analysis.

Read More >

Metallographic grinding and polishing machines can be categorized into manual and automatic machines, as well as single-disk and twin-disk configurations, with various pressure application methods. Through precise grinding and polishing, they enable accurate observation of the microstructure of samples, providing reliable data support for research and development.

Read More >