What customers truly need is not just equipment, but high-quality and reliable inspection results achieved through proper sample preparation. That is why TOPTECH offers free sample testing services, leveraging years of expertise in cutting, mounting, grinding, and polishing to develop the most suitable solutions for each application.

All samples are used solely for testing and technical validation. They are carefully labeled, stored, and returned in accordance with our internal procedures, ensuring complete protection of customer material data, process details, and R&D results, so customers can confidently entrust us with critical samples.

Through our sample testing services, we not only provide technical support but also gain a deeper understanding of customer requirements, helping to optimize processes and improve inspection efficiency. We value every collaboration and continuously transform our technical experience into better services, ensuring that every result meets accurate, consistent, and reliable standards.

| Cutting Machine | CL50, CK260B, CLM50 |

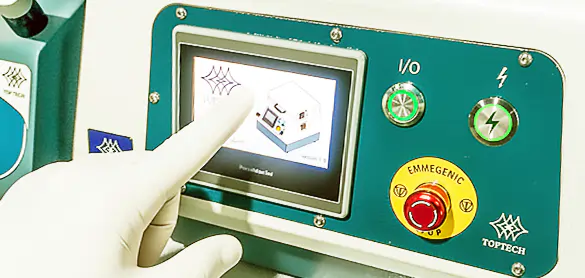

| Mounting Press | MV02A, ML32C |

| Grinding & Polishing Machine | P20G-1-R6, P20G-2-A3 |

| Grinding/Polishing/Cleaning Machine | P20GWM-2-R6 |

| Cutting | Diamond Blade, Abrasive Wheel, Cutting Fluid |

| Mounting | Epoxy Resin, Silicone Molds, Bakelite Powder, Sample Clamps |

| Grinding & Polishing | Abrasive Paper, Diamond Disc, Polishing Cloth, Diamond Suspension, Alumina Powder |