📌 Why Choose The Precision Metallographic Cutting Machine - CK200M/200B SERIES ?

Key Points

The precision cutting machine CK200B series supports up to Ø60mm cutting capacity with a low-vibration design, offering stable cutting performance and perfect cutting results. Widely used in metallographic sample preparation, it significantly accelerates subsequent sample processing.

Application

Using a feed-cutting mechanism, it is suitable for various small metallic materials including steel, iron, copper, titanium, aluminum, ceramics, spark plugs, sensors, fasteners, and more. Whether applied in the automotive industry, aerospace, manufacturing, or research/education fields, it delivers efficient and precise cutting performance, enabling high-quality samples for metallographic analysis, hardness testing, and material evaluation.

Comparison / Difference

Key Differences Between CK200M (Manual) and CK200B (Automatic)

| Specification (Spec.) |

CK200M (Manual) |

CK200B (Auto) |

Difference (Diff.) |

| Feeding Method |

Manual: Hand wheel control |

Auto (Automatic return after cutting) + Manual (Buttons & Hand wheel) |

CK200B adds automatic feeding function |

| Feeding Rate (mm/min) |

Manual: Hand wheel control |

Standard: 10~150

Option: 5~75 |

CK200B provides a specific feeding rate range (for auto-feed) |

| Total Watt (W) |

1HP: 850

2HP: 1600

3HP: 2350 |

1HP: 900

2HP: 1650

3HP: 2400 |

CK200B is 50W higher for each configuration |

| Machine Weight (kg) |

1HP: 212

2HP: 218

3HP: 230 |

1HP: 226

2HP: 230

3HP: 250 |

CK200B is heavier (approx. 12–20kg) |

The remaining specifications (such as travel distance, horsepower, noise level, cutting capacity, blade size, vise size, cooling system, power supply, etc.) are identical for both models.

Download

Interested in this product?

Click below to download the PDF catalog and access complete technical details.

Sample Testing

▎Professional · Secure · Free

✔ Free sample cutting and grinding tests

✔ Secure sample handling with strict labeling and protection

✔ Evaluation by a professional engineering team

✔ Fast feedback with recommended process solutions

Helping you quickly identify the most suitable equipment configuration and process conditions.

Contact Us

▎Response within 1 business day

Not sure which equipment or consumables to choose?

Looking for a solution for sample preparation and inspection?

From equipment selection (cutting, grinding & polishing, and mounting machines), consumable matching, and customized design modifications to complete sample preparation solutions, our 30 years of experience ensures precise recommendations and professional support.

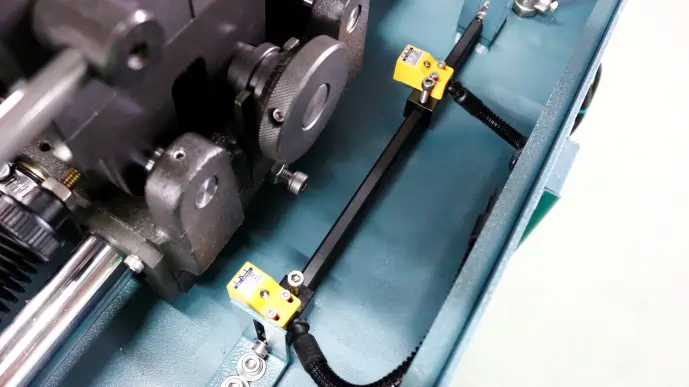

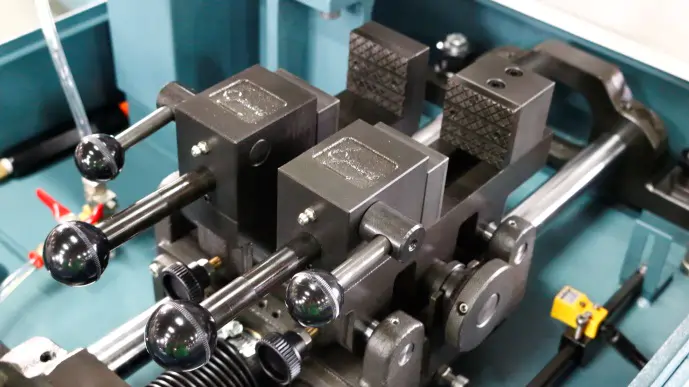

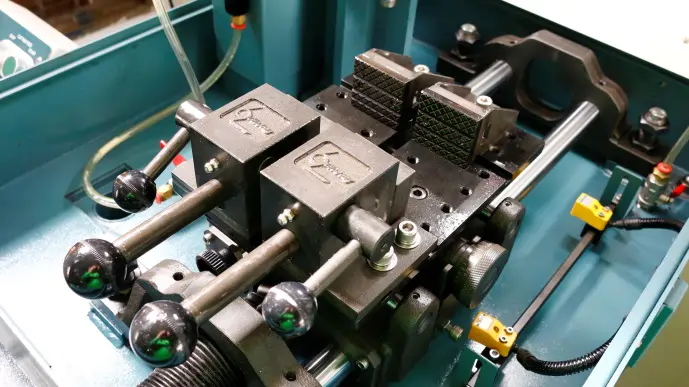

Horizontal movement vise

Horizontal movement vise