Features

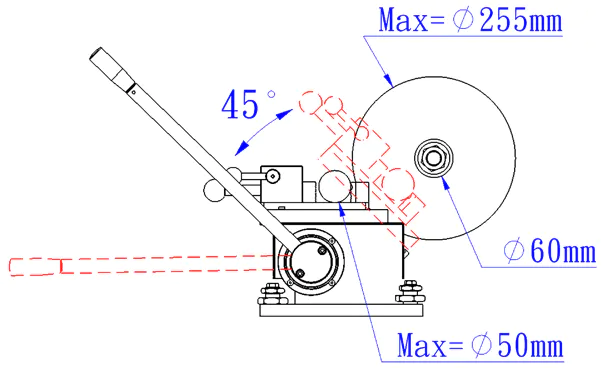

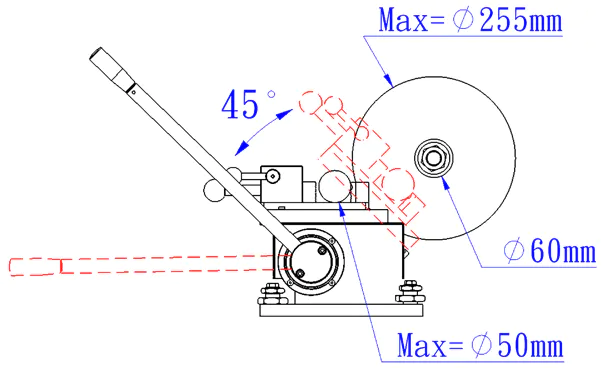

Rocker Arm Cutting

Compared with blade-travel cutting systems—where forced blade movement can easily lead to cut-off wheel fracture—the swing-arm cutting design approaches the cut-off wheel using its own weight, significantly reducing the risk of wheel breakage, and provides efficient and labor-saving operation, suitable for repetitive cutting applications to enhance cutting efficiency. This model can cut samples up to Ø50mm, compatible with various materials and sizes, ensuring precision and stability in the cutting process, reducing consumables waste, and guaranteeing consistent cutting quality.

Benchtop Precision Cutting Machine

Effectively saves space, making it ideal for laboratories, research institutions, and production environments. This type of equipment combines high performance with the advantages of a benchtop design, meeting various material cutting requirements without taking up excessive workspace, enhancing the cleanliness and efficiency of the working environment.

Safety Sensor on the Top Cover

Equipped with intelligent detection functionality, the spindle will immediately stop rotating once the top cover is opened, effectively preventing accidents and ensuring operator safety. This design not only enhances equipment safety but also complies with various industrial safety standards. It is an important mechanism for safeguarding daily operations, reducing risks associated with human error.

Magnetic Cleaning Spray Pipe

The magnetic design significantly enhances the convenience and flexibility of cleaning process. With magnetic design, users can easily adjust and position the spray pipe, preventing interference with the cutting process. This design effectively reduces conflicts between cleaning and operation, improving the workflow and efficiency.

Transparent Acrylic Top Cover

The transparent acrylic top cover not only provides excellent durability but also significantly enhances the user's field of view, making observation during operation more convenient. In addition, the acrylic material offers good impact resistance, ensuring safety and long-term stability during use.

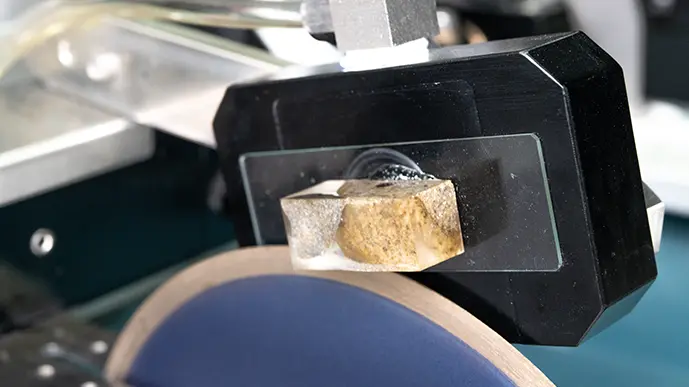

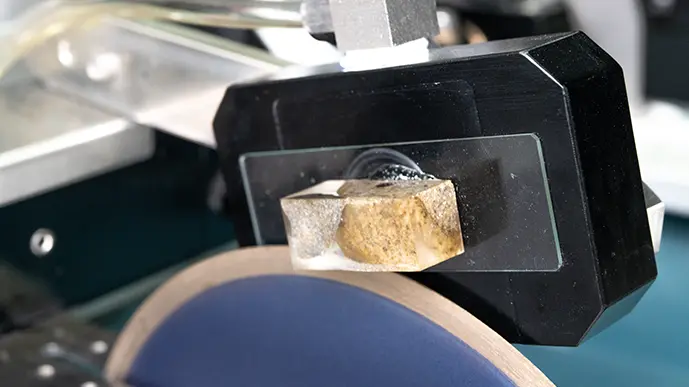

Diverse Vise Applications

Users can flexibly select or customize the appropriate vise based on the size, shape, and cutting requirements of the sample, ensuring stable clamping and operational stability during the cutting process.

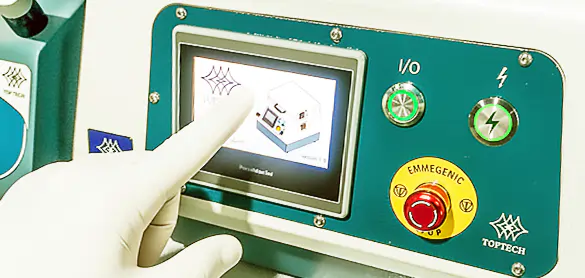

Emergency Stop

It allows users to stop the machine immediately in an emergency, effectively preventing accidents. The button is positioned noticeably and is easy to operate, ensuring that users can react quickly to reduce the risk of accincidents.

Ammeter

Effectively monitors current changes during the cutting process, providing instant feedback to the operator to ensure stability and safety. Significant current variations indicate increased cutting resistance or abnormal situations, suggesting to slow down the cutting speed to avoid overloading, which could damage the equipment or affect cutting quality.

Electromagnetic Lock Acrylic Safety Cover (Option)

Automatically locks the top cover during the cutting process to ensure operational safety. This design prevents accidental opening of the top cover during cutting, avoiding operator contact with the high-speed cut-off wheel and effectively reducing risks in the workspace. The electromagnetic lock mechanism only releases automatically after the cutting process is completed, further enhancing safety.

Magnetic Rechargeable LED Light (Option)

The magnetic LED light can be easily attached to the machine, providing auxiliary lighting to help users clearly observe the cutting process, enhancing operational accuracy and safety. The light angle can be flexibly adjusted to meet different samples and environmental requirements. The machine has a reserved socket hole for charging at any time, ensuring long-term stable use.

.jpg)