📌 Why Choose the Precision Cutting Machine – CK260B/360B/460B Series?

Key Points

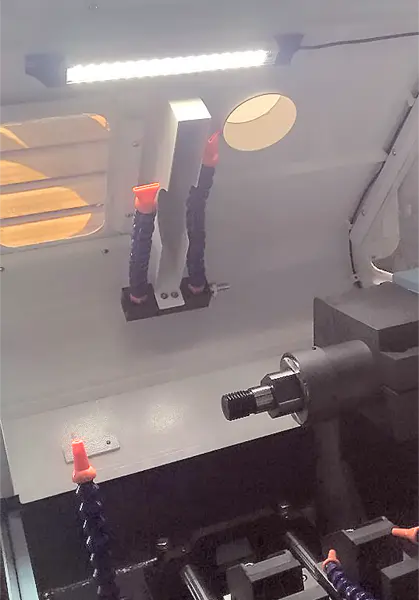

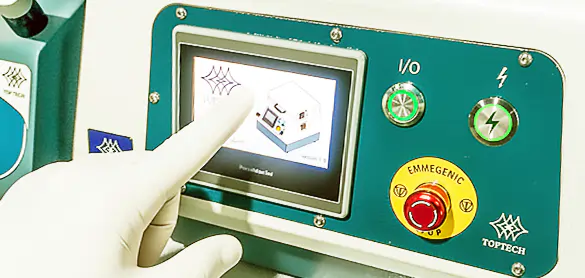

The CK260B Precision Cutting Machine Series offers a maximum cutting capacity of Ø120mm, high rigidity, low vibration, and an automation-ready heavy-duty cutting structure with industrial-grade intelligent overload protection, delivering stable and reliable cutting performance. Widely used in metallographic sample preparation, it significantly accelerates downstream processing steps.

Application

Featuring both manual and automatic feeding modes — including auto feeding and auto return — this machine is ideal for various medium-to-large metallic materials such as steel, iron, titanium, copper, aluminum, ceramics, motors, crankshafts, gears, and turbines. Whether in the automotive, aerospace, manufacturing, or academic research fields, it provides efficient and precise cutting results, delivering high-quality samples for metallographic analysis, hardness testing, and material evaluation.

Difference

Key Comparison Between CK260B, CK360B, and CK460B

| Spec. |

CK260B |

CK360B |

CK460B |

Key Difference |

| Cutting Travel (mm) |

260 |

360 |

460 |

CK460B provides the longest travel |

| Max Cutting Capacity (mm) |

Ø70 / Ø90 |

Ø90 / Ø120 |

Ø120 |

Higher models support larger workpieces |

| Cutting Power (HP) |

3 / 5 |

5 / 7.5 |

10 |

CK460B has the highest horsepower for heavy-duty cuts |

| Blade Size (inch) |

12” |

12” / 16” |

16” |

16” blades supported starting from CK360B |

| Vise Size (mm) |

130×60 |

130×60 / 170×85 |

170×85 |

Larger vises available on CK360B/CK460B |

| T-slot Table Size (mm) |

235×300 |

235×300 / 235×340 |

235×340 |

Larger table size on higher models |

| Total Wattage (W) |

2500 / 4000 |

4000 / 5800 |

7700 |

Higher tonnage requires greater wattage |

| Machine Weight (kg) |

358–365 |

454–476 |

503 |

Heavier models offer higher stability |

Other specifications (such as feeding method (automatic + manual), spindle speed (2500 / 2100 rpm), feed rate (10–75 mm/min), Y-axis travel 45 mm, 1/4HP coolant pump, AC220/380V three-phase power, and shared safety/visibility/cleaning features) are identical across all three models.

Download

Interested in this product?

Click below to download the PDF catalog and access complete technical details.

Sample Testing

▎Professional · Secure · Free

✔ Free sample cutting and grinding tests

✔ Secure sample handling with strict labeling and protection

✔ Evaluation by a professional engineering team

✔ Fast feedback with recommended process solutions

Helping you quickly identify the most suitable equipment configuration and process conditions.

Contact Us

▎Response within 1 business day

Not sure which equipment or consumables to choose?

Looking for a solution for sample preparation and inspection?

From equipment selection (cutting, grinding & polishing, and mounting machines), consumable matching, and customized design modifications to complete sample preparation solutions, our 30 years of experience ensures precise recommendations and professional support.