📌 Samples damaged during secondary clamping?

📌 Tired of repeatedly removing and re-fixturing samples between cutting and grinding?

Key Points

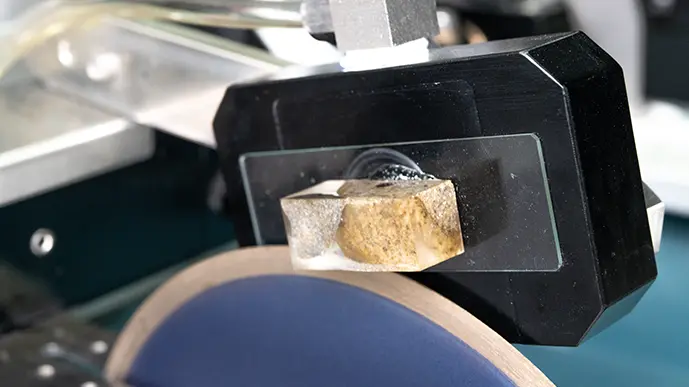

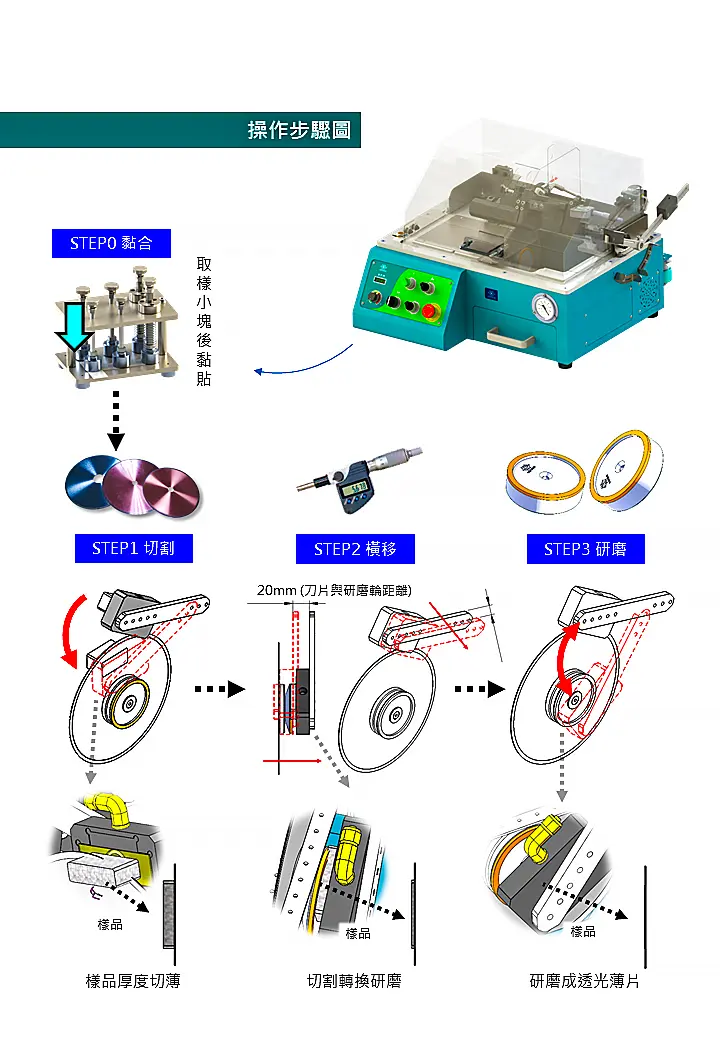

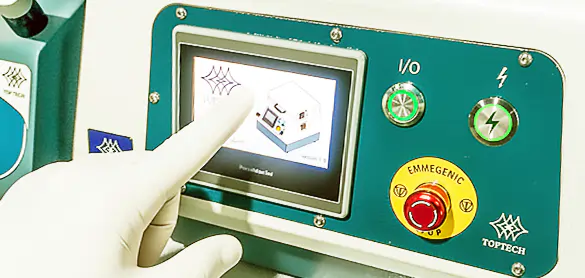

The CLG50 petrographic cutting system is specifically designed for petrography, meeting the demanding requirements of cutting and grinding hard and brittle materials. Its integrated design allows samples to be ground immediately after cutting, eliminating thickness deviation and breakage risks caused by secondary clamping.

Equipped with a 1 μm cross-feed resolution, the CLG50 can reliably produce ultra-thin rock sections down to 40 μm, cutting and grinding accuracy up to ±10 μm, ensuring clear observation of mineral crystal structures under microscopy.

By combining a vacuum clamping fixture with an automatic filtration and drainage system, the CLG50 delivers a more efficient and highly repeatable sample preparation workflow for geological research and material analysis.

Application

Utilizing an integrated bonding + cutting + cross-feed + grinding workflow, the CLG50 supports thin-section preparation for a wide range of materials, including rocks, minerals, ceramics, and other hard and brittle materials. Typical applications include rock classification, elemental analysis, texture studies, fossil research, microstructural analysis, bone and dental research, geochronology, and porosity/permeability studies related to rock degradation. Whether for geological research, inspection, material identification, or educational institutions, the CLG50 delivers efficient and precise preparation results.

Download

Interested in this product?

Click below to download the full technical brochure (PDF).

Sample Testing

▎Professional · Secure · Complimentary

✔ Free sample cutting and grinding tests

✔ Secure sample handling with strict labeling and protection

✔ Evaluation by a professional engineering team

✔ Fast feedback with recommended process solutions

Helping you quickly identify the most suitable equipment configuration and preparation conditions.

Contact Us

▎Response within 1 business day

Not sure which equipment or consumables to choose?

Looking for a solution for sample preparation and inspection?

From equipment selection (cutting, grinding & polishing, and mounting machines), consumable matching, and customized design modifications to complete sample preparation solutions, our 30 years of experience ensures precise recommendations and professional support.